Air bag suspension swaps regular metal springs for air-filled rubber bags you can adjust. When you add this to your custom build, you can raise or lower your ride height,

Key Takeaways

- Air bag suspension offers adjustable ride height and improved stability, perfect for custom builds seeking versatility in different driving conditions.

- Initial costs range from $3,000-$9,000 including installation, making it a significant investment compared to traditional suspension systems.

- Installation requires specialized knowledge and tools, often necessitating professional help to ensure proper setup and safety.

- Regular maintenance checks are essential to prevent air leaks and system failures, increasing long-term ownership responsibilities.

- Custom builds benefit from improved aerodynamics and load management, but may face higher repair costs if components fail.

What Is Air Bag Suspension

Air bag suspension swaps out regular metal springs for tough rubber bags filled with compressed air.

The system works through basic parts like an air pump, control valves, pipes, and a storage tank, which all team up to keep the vehicle riding smoothly.

The heart of this setup is a smart control system that changes the air pressure inside the rubber bags as needed. This lets drivers adjust how high the vehicle sits and how firm it rides, helping handle different weights and driving styles.

Popular in big trucks and some cars, this clever system makes sure heavy loads don't affect the ride quality by automatically balancing the air pressure where it's needed. The textile-reinforced rubber construction ensures durability and flexibility during operation. Professional-grade components deliver superior performance and reliability for custom suspension builds.

Performance Benefits and Drawbacks

Air bags in a car's suspension bring three big benefits but also come with important downsides to think about.

The system makes rides smoother by letting you change the car's height and spread out weight better, while also helping the car stay stable when turning corners. Being able to raise or lower the car helps cut down on wind resistance to save fuel and lets you drive on different types of ground. Building a custom suspension requires top-quality engine parts to ensure optimal performance and reliability.

But these good points come with some real worries about how well the system holds up.

Air suspensions often break down, with problems like air leaking out, pumps burning up, and water getting in where it shouldn't. These tricky systems need special tools and skilled mechanics to fix them. Ride height sensors constantly monitor and adjust the suspension to maintain optimal vehicle positioning.

Also, keeping them running well costs more money, and fixing them is expensive when they break. How long they last should be a key thing to think about before getting one.

Cost Analysis

Air bag suspension systems are costly to set up, with full kits running between $2,000 and $7,000 before adding labor. Looking at the parts that make up the system shows why the costs add up, with air struts and compressors being the most expensive pieces. Quality brands will offer customer support resources to help with installation and maintenance. For optimal system performance, advanced air flow through the compressor components is essential.

| Component | Price Range | Average Cost |

| Air Struts | $2,000-$3,000 | $2,500 |

| Compressor | $200-$1,000 | $600 |

| Manifolds | $120-$850 | $500 |

Having a shop put in the system adds $1,000 to $2,000 to the total cost, but doing it yourself can save money. Owners need to think about future costs too, like new air springs ($100-$1,000) and control unit updates ($100-$500). The total price changes based on what car you have, what parts you pick, and how hard it is to install.

Installation Requirements

Installing an air bag suspension system takes careful steps and safety measures.

You'll need to start with basic safety steps like unhooking the battery and making sure your car is safely lifted. You'll also need the right tools to work with parts like air springs, air pumps, and lines.

The work must be done step by step - first taking out old suspension parts, then fitting new air springs with at least ½-inch space around them. Regular motor oil changes help maintain optimal performance during installation and beyond.

You'll need to firmly attach the air pump and tank, run the air lines correctly, and do thorough testing after everything is in place.

While skilled mechanics can do this job at home, getting it done by professionals often comes with warranty coverage and ensures everything works together properly, especially since modern cars have complex electronics and suspension designs. Installation costs can range from $300 to $7000 depending on the system type and vehicle make.

Customization Options

Air suspension systems today offer many ways to customize your setup. You can pick from basic parts like height sensors, pressure gauges, and stronger air pumps to get better control of your ride, no matter what type of vehicle you have.

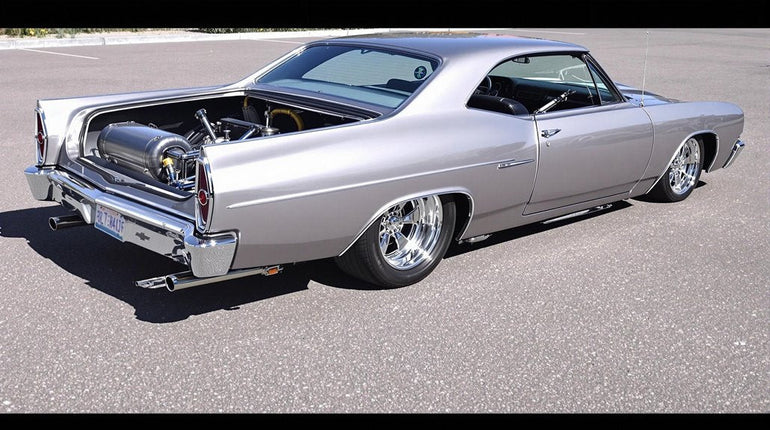

Special mounting parts help fit air bags perfectly on different vehicles, from old classics to new pickup trucks. Air struts work with your car's existing suspension parts to let you change ride height while keeping good handling.

Control systems let you save different height settings and watch air pressure in real time, and some can even get updates through wireless connections. Whether you want better performance or just want your car to look cool, you can mix and match air suspension parts to get exactly what you need.

Maintenance and Reliability

Air suspension systems can last many years when properly cared for, but they must be set up and checked regularly. Having experts install the system means all parts will fit right, with compressors and tanks firmly attached, and air lines and wiring correctly placed. Following a regular care plan keeps the system running well. Basic fixes include emptying water from air tanks every two weeks, looking for air leaks in lines, and making sure air shock locks are tight. Check parts like air filters, rubber air bags, and height sensors often. In cold places, adding air brake antifreeze stops water from freezing and damaging parts. While air suspension needs less attention than regular springs, taking these simple steps helps it work better and last longer.

Daily Driving Experience

Living with air suspension brings daily things to think about as you drive. You can set the car's height in different ways to handle all kinds of roads smoothly. While this makes driving more comfortable, you'll need to deal with less trunk space and keep an eye on water build-up.

| Aspect | Good Points | Tough Points |

| Height Control | Easy to adjust | Settings can act up |

| Storage Space | Parts fit well | Less trunk room |

| Weather Impact | Works in all weather | Must watch for water |

| System Operation | Rides smoothly | Makes some noise |

| Daily Usage | Many setup choices | Needs regular care |

To get the best from your air suspension, you need to know how it works day-to-day. Bad weather means you'll need to check for water more often, and you'll have to balance between a nice ride and practical needs by picking the right height and keeping the system in good shape.

Track and Racing Considerations

Air suspension can work well for racing when you focus on three main things: how it handles, how easily you can adjust it, and how well it holds up. With the right setup, air suspension can match how well regular racing springs work on the track.

One big plus is that you can quickly change how high the car rides without messing with spring stiffness during track days. This quick-change ability, along with good shock control and less leaning in turns, helps keep the car stuck to the track in different conditions.

But you need to think about the extra weight from air parts and how complex the system is. To do well in racing, you need top-quality parts, expert installation, and regular upkeep.

While air suspension has proven itself in racing events, you still need to watch air pressure limits and how the car cuts through the air to get the best performance.

System Components and Design

Air suspension systems use several parts working together to help vehicles ride better. The main part is rubber air bags that take the place of regular metal springs, along with a compressor (powered by electricity or the engine) that pumps air to create pressure.

The system works through air lines and valves that control air flow between the compressor, storage tank, and air bags. This setup lets drivers change how high the vehicle rides and handle different loads better.

A smart control unit watches height sensors to keep the vehicle at the right level, while strong air lines and tight connections make sure air pressure stays even.

Air springs come in different shapes and styles to match what different vehicles need.

Long-Term Investment Value

The upfront price of air suspension systems can be high, running from hundreds to thousands of dollars, but the long-term value makes it worth the money through many cost-saving benefits.

Looking at the numbers shows that owners get their money back through less upkeep, parts that last longer, and better resale prices when they sell their vehicles.

The payback comes in several ways: better gas mileage because the car cuts through the air better, less strain on tires and brakes, and fewer trips to the repair shop.

Good systems from trusted makers often come with warranties that last forever, making the investment even safer.

The system helps spread weight evenly and makes the car handle better, helping the whole vehicle last longer.

Plus, being able to change ride height and adjust settings adds real-world value that stays useful for as long as you own the car.

Frequently Asked Questions

Can Air Bag Suspension Systems Freeze in Extremely Cold Climates?

Air bags in vehicles can freeze up when it's very cold outside, which can cause problems with the air pumps and lines. To keep the system working well in winter, make sure to empty water collectors, use special anti-freeze fluid, and check that the air pump is in a good spot where it won't get too cold.

How Long Does It Take for the System to Raise From Lowest Setting?

The system usually takes between 30 to 90 seconds to lift up from its lowest point. The speed changes based on how well the system works, how strong the pump is, and how much air it needs. Things like pressure in the tank, weight being carried, and the power of the air pump affect how quickly it rises.

Does Air Suspension Affect Vehicle Insurance Rates?

Air suspension changes usually make your insurance cost more money. You'll need to tell your insurance company about these changes. Insurance companies look at how safe the system is and who put it in before deciding how much extra to charge you.

Can You Manually Operate Air Suspension if the Electronics Fail?

Air suspension can still work even if the electronics break down, thanks to backup hand controls that let you pump air in or release it from the springs to keep the suspension working when needed.

What Happens to Handling Characteristics When an Air Bag Suddenly Fails?

When an air bag fails without warning, the car's corner drops down right away, making the car sit unevenly. This throws off how weight is spread across the wheels. The car becomes harder to steer safely and might not grip the road as well, which can make driving risky.

Conclusion

Air bag suspension systems represent a significant technological investment that demands careful consideration of multiple engineering factors. The combination of adjustable ride height, load management capabilities, and customization potential must be weighed against maintenance requirements, system complexity, and initial cost outlays. For performance applications, the dynamic response characteristics and pressure-based damping properties make air suspension a viable option when precise suspension control and adaptability are paramount considerations. Gexhaust specializes in custom air suspension solutions. To learn more about our air bag suspension options, contact us for expert guidance.